Aluminum Foil

- China

- 7-10 days

- 100 Tons/Month

Wide assortment of Aluminum Foil and thousands of other foods delivered to your home or office by us. Save money on your first order.

Aluminum Foils, Thickness: 0.005 - 0.20 Mm

Temper

O-H19

Type

Roll

Thickness

0.005 - 0.20 mm

Length

7.6 - 300 mtr

Width

30 cm,45 cm

Aluminum foil

Aluminum foils are available in various alloys

Aluminum foil is characterized by its alloy and the material state. Pure aluminum (i.e., 100%) does not exist on the market, but other metals and semimetals are bonded to the aluminum in an alloy. These are mainly chromium, copper, iron, magnesium, manganese, silicon, titanium and zinc.

These elements are often only added in fractions of one percent, but can strongly influence the properties of the aluminum. For this reason, different alloys are preferred for different applications.

Alloys are given in various notations. International EN-AW notation (eg EN-AW 1050 with at least 99.5% aluminum or EN-AW 8079) is used internationally. In Germany, sometimes the old DIN notation is used (eg AlMg3 for EN-AW 5754).

The alloys differ only insignificantly in price, but some alloys are produced less frequently than others. Such aluminum alloys are therefore more difficult to obtain, especially when a small quantity is demanded.

| Thickness | 0.0055-20mm |

| Width | MAX2500mm |

| ID | as your require |

| MOQ | 2 tons |

| Standard | ASTM, EN,GB/T 3198-2010 |

| Certification | ISO9001,ROHS,TUV |

Color Coated Aluminum Coil Specification

Coating finish: PVDF, POLYESTER, ACRYLIC

Aluminum coil/foil/plate thickness: 0.024mm-1.20mm

Standard width: 1240mm

Special width: 50mm-1700mm

Coils core diameter: 150mm ,405mm, 505mm, 508mm, 510mm

Coating thickness: PVDF >=25micron POLYESTER>=18micron

Gloss: 10-90%

Coating hardness (pencil hardness): more than 2H

Coating adhesion: no lower than first grade

I mpact resistance: No cracking and peeling (50kg/cm,ASTMD-2794:1993)

Flexibility

MEK resistance: more than 100 times

Available Specification Coil/Foil/Plates: |

| ITEMS | ALLOY | END USE | TEMPER | THICKNESS(MM) |

| 1XXX SERIES | 1050PS LITHO SHEET STOCK CTP CTP STOCK | PRINTING | H18 H16 | 0.14—0.27 |

| 1050 1060 1060 1070 1100 ANODIZING STOCK DEEP-DRAW STOCK | COSMETIC CAP STOCK CAP STOCK ALUMINUM CIRCLE STOCK ACP STOCK TREAD PLATE SPECULAR SHEET CABINET SHEET LIGHTING COMPONENT STOCK CAPACITOR SHELL STOCK | ALL TEMPERS | 0.2—4.5 | |

| 1A99 1070 1235、1100 FOIL AND FOIL STOCK | CAPACITOR FOIL, HOUSEHOLD FOIL, FOIL STOCK | H14 H18 | 0.02—0.3 | |

| 3XXX SERIES | 3105 3003 3A21 3004 3005 | BATTERY SHELL STOCK TREAD PLATE CABINET SHEET PRESSURE CONTAINER STOCK BEVERAGE CONTAINER STOCK HIGH-PERFORMANCE DEEP DRAW MATERIAL | ALL TEMPERS | 0.2—4.5 |

| 3003 CAPACITOR FOIL | CAPACITOR FOIL | H18 | 0.02—0.05 | |

| 5XXX SERIES | 5251 5052 5754 5182 5083 5005 | ANODIZING MATERIAL,DEEP DRAW STOCK,TREAD PLATE,ELASTIC CAP STOCK,TRANSPORTATION | ALL TEMPERS | 0.3—100 |

| 6XXX SERIES | 6061 6063 6A02 | QUENCHED, PRE-STRETCHED, TREAD PLATE | TX | 0.3—200 |

| 4XXX SERIES, 7XXX SERIES | 4343、4004、 4104 7072 | CLADDING FOIL, SHEET, AND PLATE | ALL TEMPERS | 30—90 |

| 8XXX SERIES | 8011 8021 8079 FOIL AND FOIL STOCK | BEVERAGE FOIL CABLE FOIL BLISTER FOIL HOUSEHOLD FOIL CONTAINER FOIL PP CAP STOCK FOIL STOCK | ALL TEMPERS | 0.01—0.3 |

3003 Aluminum foil

3003 aluminum foil is a common material for making aluminum honeycomb cores, its temper is h18, and it has the advantages of clean degreasing, high strength, and flat shape.

The lunch box made of 3003-H22 aluminum foil is light in weight, meets the national food safety and hygiene standards, and will not produce harmful substances. And easy to recycle, it is a kind of renewable resource;

3003 aluminum foil is a commonly used aluminum foil for packaging. The commonly used tempers are H14, H16 and H18.

3003 Aluminum foil

3003 aluminum foil is a common material for making aluminum honeycomb cores, its temper is h18, and it has the advantages of clean degreasing, high strength, and flat shape.

The lunch box made of 3003-H22 aluminum foil is light in weight, meets the national food safety and hygiene standards, and will not produce harmful substances. And easy to recycle, it is a kind of renewable resource;

3003 aluminum foil is a commonly used aluminum foil for packaging. The commonly used tempers are H14, H16 and H18.

Aluminum foils from soft to hard, and degreased

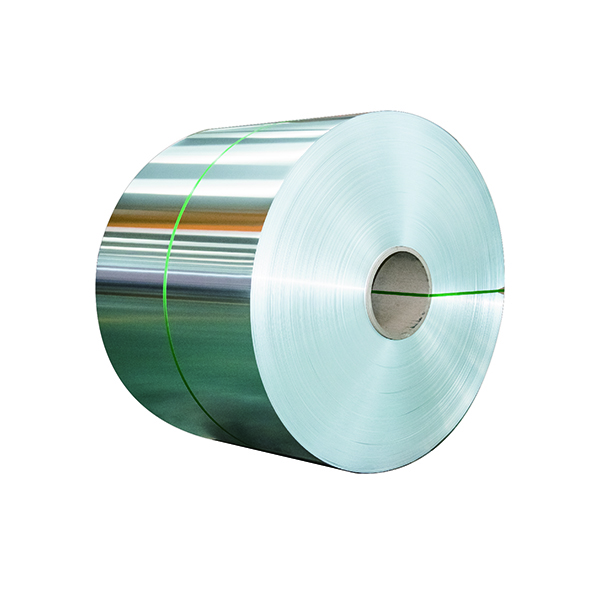

Aluminium foil as a reel

Aluminum foil on reel

In addition to the alloy, the material temper also has an influence on the properties of the aluminum. A distinction is made here between “soft” and “hard” aluminum, as well as the intermediate forms “quarter hard”, “semi hard” and “three-quarter hard”.

After (several times) rolling operations, the aluminum is in a hard condition. If the rolls are then heated for several hours in an oven, the material is transformed to a soft state. In addition, rolling oil residues also evaporate on the film. This is particularly important for the production of laminates, because oil residue is degrading or preventing the adhesion of the adhesive. For laminates, mainly soft aluminum is used. This also applies to coatings – most of the lacquers also do not adhere to films with oil residues.

If, however, aluminum foil is to be used in the “hard” state for laminates and lacquered films, the films can also be degreased chemically. The aluminum foil is “washed” by a bath in chemical substances instead of heating the foil in the oven.

Composite films made of aluminum with PET, PE, paper and other materials

Multilayer films are referred to as laminates or composite films. These are multilayer films made of different materials, the individual layers being glued together.

Golden Aluminum foil with paper

Multi-layer foil of gold-printed aluminum foil with paper

A laminate of two films is called “duplex” (eg aluminum + PE), a laminate of three layers is also called “triplex” (e.g. PET + aluminum + PE). Laminates with more layers are also possible, “Aluminum 7 μ + PE 15 g + kraft paper 50 g / m² + sheeting 6 mm x 12 mm + flame retardant PE 25 g”. This material can be used several times (e.g. two PE films in a sandwich with aluminum, i.e. PE + Alu + PE).

The process of gluing the films is called “laminating” or “lamination“. When a plastic material is applied to a carrier web in liquid form, it can itself serve as an adhesive for a further film. For this purpose, a PE granulate is usually heated and applied between the two foils to be bonded. One then speaks of a “PE-lamination“. When the PE is applied to only one carrier (i.e. outside the finished film), it is referred to as “coating” or “extruding“.

Mechanical properties of aluminum foil

The most important (mechanical) properties for films and tapes are the tensile strength, the yield strength and the elongation. These properties are important both for single-layer foils (ie, for example, pure aluminum foils) and for laminates.

In the case of laminates, adhesion is also important. The bonded adhesion is used to indicate how well the individual layers adhere to each other. Depending on the application, characteristics such as degree of gloss, water permeability and vapor permeability, or the degree of emissivity also play a role.

Dimensions of aluminum foil and roll design

When purchasing aluminum foil and strips, the thickness and width of the foil should be indicated. For aluminum foils the thickness will be specified in micrometers (μm = 1/1000 millimeters). The unit millimeter (mm) is also used for thicker aluminum strips. The width is generally expressed in millimeters, but also centimeters (cm) or meters (m) are common.

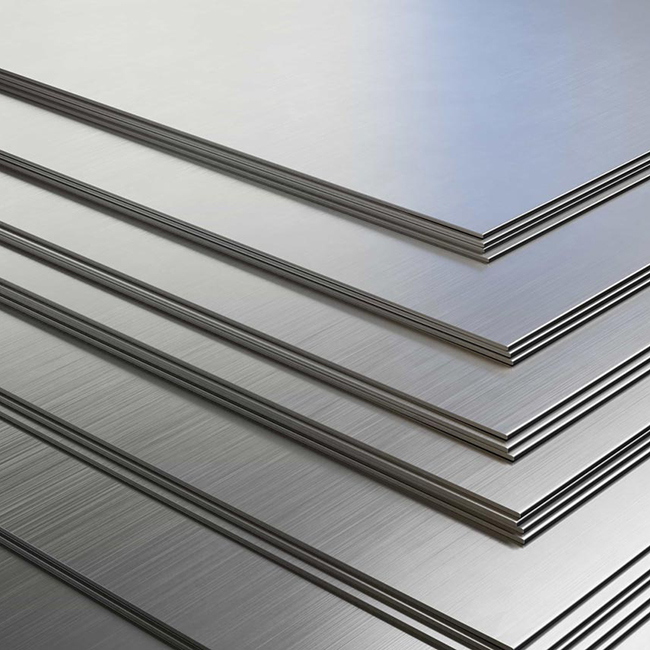

Stacked aluminum strips

Aluminum strips

In addition to the thickness and the width, the roll presentation/format is also important. Rolling is defined as the weight, the reel outside diameter (OD) and the lineal meter or length per reel. These are frequently limited by the further processing steps, for example, a further processing machine can only pick up rollers with a certain maximum weight or maximum outer diameter.

In addition, there are different core materials. For aluminum reels of several hundred kilograms steel cores with an inside diameter (ID) of 150 mm or 152 mm are mainly used. For small reels with an internal diameter of 38 mm, 40 mm, 70 mm or 76 mm are also used cardboard cores. Laminates are often wound on cardboard cores with an inner diameter of 76 mm. Cores made of aluminum or plastic are more rarely used.